Solutions

Integrated Solutions

Quickly narrow your search using filters on the specifications that matters the most to your applications. Feel free to send an online RFQ, email or call us. Our experienced staff is ready to review your requirements and assist you in choosing the right solution for your application.

Hikrobot Smart Cameras set the standard for precision, durability, and cost-effectiveness in automated quality control. With advanced imaging and AI capabilities, they streamline complex inspections across manufacturing applications.

Smart code readers are essential for precise and efficient barcode and QR code reading in industry. These devices ensure reliable data capture with high-resolution sensors, sophisticated processing algorithms, and robust communication protocols.

Coretec's Assembly Servo Press is a cost effective solution with superior force & displacement control, built-in monitoring & data collection. Next-gen Assembly Servo Technology is now in reach, so improve production efficiency and make less scrap

Coretec Nutrunners are durable, integrated fastening systems, with torque & angle feedback, signature analysis & data collection. Looking for a superior tightening speed & control, in a simple to program, cost effective package? You’ve found it.

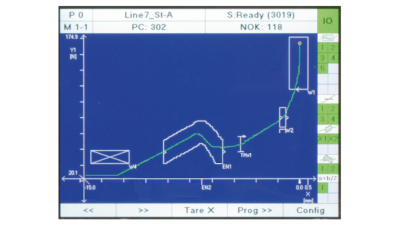

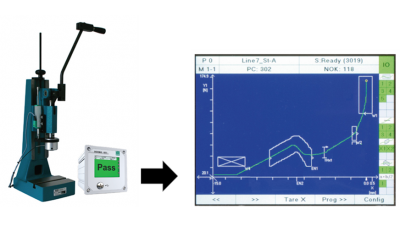

Allow us to apply our over 30 years of experience in press monitoring to your assembly applications. Hand, Pneumatic, Air-Over-Oil & Hydraulic presses are compatible with our monitoring solutions, which include sensors & data collection solutions.

An all-in-one manual workstation with a calibrated press, advanced sensors, and analysis electronics—ready for immediate use and precise performance monitoring.

Pneumatic Assembly Press with Force Monitoring for 100% Quality Control High-Performance Assembly Solutions for Automotive, Aerospace, Electronics, and Medical Manufacturing

Coretec Servo presses are known for their precise control of force and position, high operating speeds, and low energy consumption. These machines are customizable and used in a variety of manufacturing applications.

Absolute Gauge Technologies. is the North American Distributor for ForTest, offering a full range of leak testing systems and flow testers for a wide range of applications across the automotive, medical, consumer products, and aerospace industries.

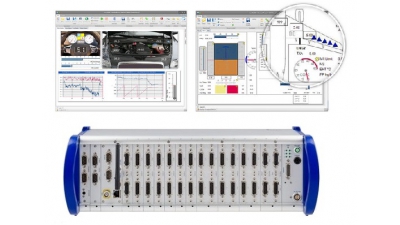

By focusing on test & measurement productivity, imc creates tools which empower engineers to deploy data acquisition and control systems efficiently, meeting the test and measurement challenges of manufacturing and development departments.

We've been providing turnkey Function Test Systems with Monitoring for over 25 years. From valve testing to seat slide exercise we have sensors to fit, cables to connect, controllers & data collection software for 100% inspection and traceability.

Complete 24 bit weighing controllers with built in powerful digital filters, Integrated web server is standard. There are custom firmware versions to support all your weighing applications. Powerful features are configured via the free PC software.

Speed monitoring with Sensors and Instrumentation for monitoring and safety protection of rotating machinery. Single and multiple input modules that can provide reliable and economical solutions for overspeed protection.

Sensors & Instrumentation used by design and test engineers as well as quality control and maintenance staff to test and measure vibration, acoustics, pressure, force, load and shock in research, development, certification and quality assurance.

Precise and Dynamic measurements from sensors & energy sources, that are transmitted wirelessly and converted to analog signals or engineering units, as part of a data stream.

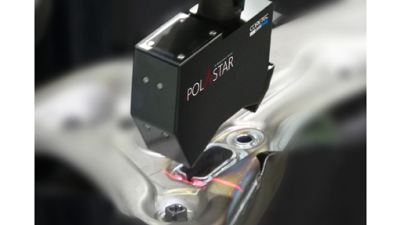

AGT brings you Coretec's 3D Weld Inspection System POLASTAR, an innovative, patented solution that fully automates your weld inspections. Combining 3D camera technology and robotics, it ensures fast and precise results for a wide range of weld types.

Transform your material handling and logistics with Hikrobot Autonomous Mobile Robots (AMRs). These intelligent robots are designed to optimize your operations, reduce costs, and improve safety, bringing next-generation automation within reach.

A no-code, out-of-the-box MES built for discrete manufacturing. PINpoint Essentials brings real-time visibility, full traceability, and smarter operator performance to every station on your plant floor—fast to deploy, easy, and built to deliver.